|

|

2014-03-21

, 17:38

|

|

|

Posts: 5,028 |

Thanked: 8,613 times |

Joined on Mar 2011

|

#262

|

AIUI, _David_ mean the scrapped PCB on sides of the port, made when reinforcing USB port via dr_frost_dk's method. Of course, all of above post's advices apply - I would just add that you need to be sure that your heating iron is hoy enough (you're literally soldering to whole ground plane), and that you're soldering to copper there, so flux that works on USB port's shield may be not appropriate.

/Estel

/Estel

__________________

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

| The Following User Says Thank You to Estel For This Useful Post: | ||

|

|

2014-03-26

, 18:48

|

|

Posts: 184 |

Thanked: 75 times |

Joined on Mar 2011

@ UK

|

#263

|

Hi all,

My phone's usb seems to be repaired but is still not charging. Does anyone have a picture of where the fuse is located?

My phone's usb seems to be repaired but is still not charging. Does anyone have a picture of where the fuse is located?

__________________

#1 Nokia N900 Feb- 2011 - June - 2013 (Dead motherboard)

#2 Nokia N900 July-2013 (CSSU Stable) - Present

#3 Nokia N900 April-2014 (CSSU Thumb) - Present

#1 Nokia N900 Feb- 2011 - June - 2013 (Dead motherboard)

#2 Nokia N900 July-2013 (CSSU Stable) - Present

#3 Nokia N900 April-2014 (CSSU Thumb) - Present

| The Following User Says Thank You to Ast007 For This Useful Post: | ||

|

|

2014-03-26

, 18:59

|

|

Posts: 71 |

Thanked: 177 times |

Joined on Aug 2013

|

#264

|

Originally Posted by _David_

All I know is, that "ball-like behavior" is normal for molten metals. Are you using rosin flux or something?

I cannot get solder to stick to the PCB. I've scraped off a 2mm strip, heated it, added flux with pen, reheated, added rosin solder (lead-free) and it won't stick. It will occasionally form ball-like blobs that look attached but come apart under minimal force.

Solder sticks to the metal cage of the USB port fine.

I've never been very good at soldering but I'm starting to think it's my tools more than me.

Any advice?

|

|

2014-04-11

, 00:29

|

|

Posts: 131 |

Thanked: 184 times |

Joined on Dec 2011

|

#265

|

Entirely the fault of the lead-free solder. I ordered some lead rosin-cored solder from eBay and it flowed from the bubble within a second.

Unfortunately, N900 is now dead. I'd previously used a hotter iron to remove the old lead-free solder but didn't touch anything I wasn't supposed to.

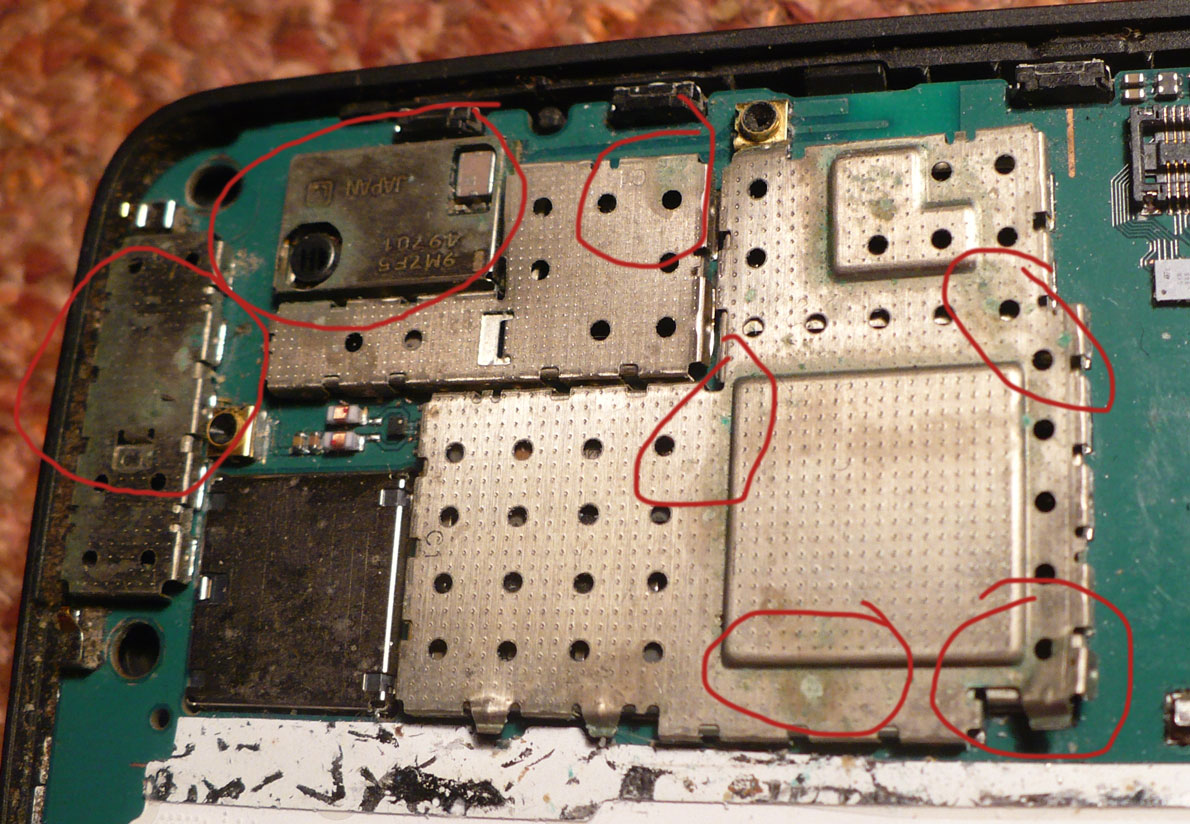

About a minute after soldering, I put the battery in and the N900 seemed to stay warm, particularly the big raised bump in the shielding here:

http://http://wiki.maemo.org/images/...connectors.png

The really annoying thing is I didn't have a backup. I was fixing the USB to rescue it from the BackupMenu flaw which bricks your phone if you restore an old kernel.

Unfortunately, N900 is now dead. I'd previously used a hotter iron to remove the old lead-free solder but didn't touch anything I wasn't supposed to.

About a minute after soldering, I put the battery in and the N900 seemed to stay warm, particularly the big raised bump in the shielding here:

http://http://wiki.maemo.org/images/...connectors.png

The really annoying thing is I didn't have a backup. I was fixing the USB to rescue it from the BackupMenu flaw which bricks your phone if you restore an old kernel.

| The Following User Says Thank You to _David_ For This Useful Post: | ||

|

|

2014-04-12

, 14:30

|

|

|

Posts: 5,028 |

Thanked: 8,613 times |

Joined on Mar 2011

|

#266

|

I'm afraid you might have, accidentaly shortcut something with a small drop of solder, that landed somewhere where it shouldn't. Or, what is also possible, you heated part of N900 too much, and it burned something out (if you're sure that the former is not the case).

Remember that during soldering electronic, much hotter soldering iron used for shorter time is better than cooler one, but used longer (heat transfer). I would risk saying that you want to have as hot iron as you can (up to sane limits, but I guess we won't be talking about hard solder range), but very, very quick soldering operation.

Also, just for the record - inability to restore backups from older kernel isn't "backupmenu flaw" - it's classical ERROR_USER, precisely, the lack of understanding what BackupMenu is exactly backupping during rootfs backup (include kernel modules, but not the kernel, as it is not on rootfs). Also, it is possible to recover from it manually, by copy'ing proper modules for given kernel to rootfs (but it's off-topic here, os ask in backupmenu thread - not that it help after your N900 is fried, though).

Sorry for your loss

/Estel

Remember that during soldering electronic, much hotter soldering iron used for shorter time is better than cooler one, but used longer (heat transfer). I would risk saying that you want to have as hot iron as you can (up to sane limits, but I guess we won't be talking about hard solder range), but very, very quick soldering operation.

Also, just for the record - inability to restore backups from older kernel isn't "backupmenu flaw" - it's classical ERROR_USER, precisely, the lack of understanding what BackupMenu is exactly backupping during rootfs backup (include kernel modules, but not the kernel, as it is not on rootfs). Also, it is possible to recover from it manually, by copy'ing proper modules for given kernel to rootfs (but it's off-topic here, os ask in backupmenu thread - not that it help after your N900 is fried, though).

Sorry for your loss

/Estel

__________________

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

| The Following User Says Thank You to Estel For This Useful Post: | ||

|

|

2014-04-13

, 05:33

|

|

Posts: 131 |

Thanked: 184 times |

Joined on Dec 2011

|

#267

|

The only place solder could have got is inside the USB cage. I doubt there's a serious short-circuit potential in there?

With the hotter iron (40W), I might have placed the tip on the cage for a few seconds. Considering the amount of heating up of the PCB I did with the cooler iron (25W) trying to get the leadfree to bond, as well as the numerous times I touched things I wasn't supposed to (the camera mount got a bit melted)... it seems both unlucky and odd.

Something else that may be relevant: there's a distinctive green colour covering the same shielding that was hot that I never noticed prior to the soldering. It could be related to the green PCB or it looks a bit like copper oxide.

With the hotter iron (40W), I might have placed the tip on the cage for a few seconds. Considering the amount of heating up of the PCB I did with the cooler iron (25W) trying to get the leadfree to bond, as well as the numerous times I touched things I wasn't supposed to (the camera mount got a bit melted)... it seems both unlucky and odd.

Something else that may be relevant: there's a distinctive green colour covering the same shielding that was hot that I never noticed prior to the soldering. It could be related to the green PCB or it looks a bit like copper oxide.

|

|

2014-04-13

, 05:49

|

|

|

Posts: 6,445 |

Thanked: 20,981 times |

Joined on Sep 2012

@ UK

|

#268

|

Originally Posted by _David_

Hmm. Not sure what the implication of a short circuit between one of the data pins and one of the power pins would be.

The only place solder could have got is inside the USB cage. I doubt there's a serious short-circuit potential in there?

Anyway, that should be quite easy to detect with a simple multimeter.

Something else that may be relevant: there's a distinctive green colour covering the same shielding that was hot that I never noticed prior to the soldering. It could be related to the green PCB or it looks a bit like copper oxide.

Oxidized shield is quite common. Although it looks unsightly, it should not result in the heating issue unless combined with something else.

__________________

Русский военный корабль, иди нахуй!

Русский военный корабль, иди нахуй!

| The Following User Says Thank You to pichlo For This Useful Post: | ||

|

|

2014-04-13

, 14:38

|

|

|

Posts: 5,028 |

Thanked: 8,613 times |

Joined on Mar 2011

|

#269

|

If you have heated PCB so much with 25W iron, the 40W could just "finish the job". I don't think touching shield was the problem, I think that it was heat transfer from the part you were soldering. Then, the part that got burned/short internally heated when you inserted battery - probably, very much, until it burned out. The heat you detected on shiekld was only aftermatch, probably. Green oxide on it was an effect IMO, not the cause.

If you're interested, youi may remove shield (doesn't require desoldering, you can do it with your fingernails), and check how that part look... And smell. Smell of burned electronic (in the morning ) is very distinctive, even few days after failure.

) is very distinctive, even few days after failure.

/Estel

If you're interested, youi may remove shield (doesn't require desoldering, you can do it with your fingernails), and check how that part look... And smell. Smell of burned electronic (in the morning

) is very distinctive, even few days after failure.

) is very distinctive, even few days after failure./Estel

__________________

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

N900's aluminum backcover / body replacement

-

N900's HDMI-Out

-

Camera cover MOD

-

Measure battery's real capacity on-device

-

TrueCrypt 7.1 | ereswap | bnf

-

Hardware's mods research is costly. To support my work, please consider donating. Thank You!

| The Following User Says Thank You to Estel For This Useful Post: | ||

|

|

2014-04-25

, 21:33

|

|

Posts: 131 |

Thanked: 184 times |

Joined on Dec 2011

|

#270

|

The green patches near the lens hardly came out but they all look like the patches on the left.

The shielding isn't easy to remove due to adjacent shields and I've yet to succeed. There was no burning smell unless it was entirely held in by the shielding.

Русский военный корабль, иди нахуй!